Air conditioner compressor will not flip off? This irritating downside can depart you sweltering within the warmth. Understanding the intricacies of your AC’s compressor, from its electrical connections to exterior environmental components, is vital to diagnosing and fixing the difficulty. We’ll delve into step-by-step troubleshooting, exploring frequent causes and efficient options.

From defective sensors to improper upkeep, quite a few components can contribute to a compressor refusing to close down. This information will present a complete strategy, empowering you to establish the basis trigger and restore your AC’s cooling effectivity. We’ll additionally have a look at preventive upkeep, serving to you keep away from future issues and lengthen the lifetime of your unit.

Compressor Management Methods

Fashionable air conditioners rely closely on subtle management techniques to make sure optimum efficiency and vitality effectivity. These techniques exactly regulate the compressor’s operation, stopping pointless put on and tear, optimizing cooling output, and minimizing vitality consumption. Understanding these management techniques is vital to diagnosing and resolving points when a compressor malfunctions.The intricate community of sensors, actuators, and management logic inside an air conditioner’s compressor management system determines how the compressor operates.

A cussed air conditioner compressor refusing to close off generally is a irritating challenge. This typically factors to underlying issues, resembling a defective management board or a refrigerant leak, which generally manifests in your warmth pump blowing cool air. Diagnosing the exact root trigger is essential to fixing the air conditioner compressor will not flip off downside successfully.

Troubleshooting this challenge, nonetheless, ought to contemplate if the warmth pump is blowing cool air as an alternative of heat air, which requires a special strategy, as detailed on this useful information: heat pump blowing cool air. Understanding this connection is vital to resolving the air conditioner compressor will not flip off challenge correctly.

This automation, whereas seemingly easy, entails complicated calculations and real-time changes to take care of the specified temperature. From easy on/off cycles to classy algorithms adjusting velocity and frequency, these techniques always monitor and react to the ambient temperature and person settings.

Forms of Management Methods

Several types of management techniques are employed in air conditioners, every providing various levels of sophistication and effectivity. The number of the management system typically is dependent upon the particular wants and options of the air conditioner unit.

Troubleshooting an air conditioner compressor that will not shut off generally is a irritating expertise. This challenge, typically stemming from electrical issues or defective elements, requires cautious prognosis. Fortuitously, understanding the intricacies of basic automobile restoration, like discovering the proper 1955 Chevy Bel Air door panels here , can supply invaluable insights into the mechanics of techniques.

Finally, correct electrical diagnostics are essential to resolve the air conditioner compressor challenge.

- On/Off Management Methods: These primary techniques function the compressor in a easy on/off cycle. The compressor activates when the temperature rises above a pre-set threshold and turns off when the temperature reaches the specified setting. This methodology, whereas simple, can result in important vitality waste if the temperature fluctuations are frequent or massive.

- Thermostatic Enlargement Valve (TXV) Methods: On this system, a TXV controls refrigerant stream, instantly impacting compressor operation. By adjusting the refrigerant stream primarily based on temperature and stress, the compressor is simply activated when wanted, enhancing vitality effectivity.

- Variable Pace Drives (VSD): VSDs supply a big development in effectivity by adjusting the compressor’s velocity in response to temperature variations. This methodology optimizes vitality use by solely operating the compressor on the vital velocity, moderately than a hard and fast velocity as in on/off techniques.

Effectiveness of Management Mechanisms

The effectiveness of a management mechanism in stopping compressor overwork relies upon critically on its means to reply promptly and precisely to temperature modifications. Fast and exact responses reduce the variety of begin/cease cycles, which reduces put on and tear on the compressor. Methods with variable velocity drives (VSD) show superior efficiency on this regard, as they’ll modify the compressor velocity in real-time to take care of the specified temperature with out extreme biking.

Troubleshooting a cussed air conditioner compressor that refuses to close off generally is a actual headache. Generally, a easy verify of {the electrical} connections or a stress aid valve adjustment can repair the issue, however extra complicated points would possibly require a deeper dive. For example, a malfunctioning c15 cat air compressor may probably trigger an overload, resulting in the compressor remaining engaged.

Finally, addressing the basis reason for the air conditioner compressor’s persistent operating is vital to restoring correct operation.

- On/Off techniques typically lead to extra frequent start-up and shut-down cycles, probably resulting in greater put on and tear on the compressor and decreasing general system longevity.

- TXV techniques enhance effectivity in comparison with on/off techniques, however their responsiveness might not match VSD techniques, which might react to small temperature fluctuations extra dynamically.

- VSD techniques supply the simplest resolution by dynamically adjusting the compressor velocity, resulting in lowered vitality consumption and fewer pressure on the compressor. That is particularly noticeable in environments with fluctuating temperatures.

Typical Management System Diagram

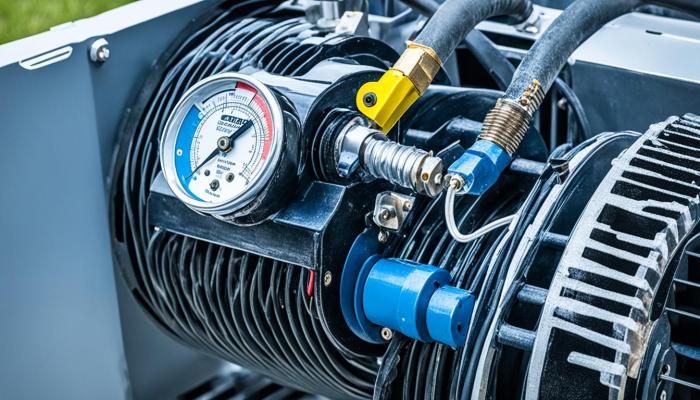

A typical management system diagram for an air conditioner depicts the stream of alerts and the interplay between numerous elements. The diagram visually represents the sequence of occasions from the temperature sensor detecting a temperature change to the compressor beginning or stopping.

Troubleshooting a cussed air conditioner compressor that refuses to close off generally is a irritating house owner expertise. Fortuitously, understanding the nuanced workings of the cooling system, just like the important function of a correctly functioning hib air 40 mirror, hib air 40 mirror , can typically pinpoint the basis trigger. This typically results in a faster and extra environment friendly resolution to the persistent compressor challenge.

A diagram would illustrate the sensor(s) (temperature and stress), the management board, the compressor motor, and the relays or valves. The arrows would present the course of sign stream, from sensor readings to the management board after which to the actuators (compressor, valves). Several types of management techniques can have totally different elements, however the basic precept stays the identical.

Exterior Components and Upkeep

Air conditioner compressors, the guts of your cooling system, are prone to a variety of exterior components and require diligent upkeep to make sure optimum efficiency and longevity. Understanding these parts is essential for stopping pricey repairs and sustaining a snug indoor surroundings. Poor upkeep can result in untimely compressor failure, elevated vitality consumption, and potential security hazards.Environmental circumstances considerably influence compressor operation.

Excessive temperatures, whether or not excessively sizzling or chilly, can pressure the compressor’s elements. Excessive humidity can result in corrosion and cut back the effectivity of the cooling course of. Moreover, fluctuating energy provide may cause compressor instability, resulting in untimely put on and tear. Understanding these exterior influences permits for proactive measures to mitigate their destructive influence.

Environmental Affect on Compressor Operation, Air conditioner compressor will not flip off

Assorted environmental circumstances can influence the efficiency and lifespan of air conditioner compressors. Excessive temperatures, whether or not extreme warmth or frigid chilly, can instantly have an effect on the compressor’s effectivity and sturdiness. Excessive humidity ranges enhance the chance of corrosion throughout the compressor’s elements, probably decreasing its operational lifespan. Fluctuations within the energy provide may cause compressor instability, resulting in elevated put on and tear and probably triggering security mechanisms.

Proactive methods to deal with these circumstances are essential to sustaining a steady and environment friendly cooling system.

Significance of Common Upkeep

Common upkeep is important for sustaining the optimum efficiency and increasing the lifespan of your air conditioner compressor and associated elements. Preventive measures can establish potential points earlier than they escalate into main issues, decreasing restore prices and guaranteeing environment friendly cooling. Immediate consideration to routine upkeep duties can improve vitality effectivity, enhance the general efficiency of the air con system, and reduce potential security dangers.

Troubleshooting an air conditioner compressor that will not shut off generally is a irritating expertise. A standard offender is a defective capacitor or overload relay, however generally a extra highly effective resolution is required, like upgrading to a ten hp air compressor single section. This type of compressor would possibly supply the required energy to deal with the load and guarantee dependable operation.

Nonetheless, earlier than changing elements, an intensive inspection {and professional} prognosis are important to pinpoint the precise challenge.

Affect of Refrigerant Ranges on Shutdown Mechanisms

Improper refrigerant ranges can considerably have an effect on the compressor’s shutdown mechanisms. Inadequate refrigerant can result in inadequate cooling, inflicting the compressor to overheat and probably set off a shutdown. Conversely, extreme refrigerant may disrupt the compressor’s operation and security controls. Correct refrigerant cost ranges are important for optimum compressor efficiency and to keep away from untimely failures or issues of safety.

Preventive Upkeep Duties

A proactive strategy to compressor upkeep is essential for longevity and effectivity. Common checks and procedures assist establish potential issues early, avoiding costlier repairs down the road. These preventive upkeep duties needs to be carried out by certified technicians to make sure accuracy and security.

- Visible Inspection: An intensive visible inspection of the compressor and surrounding elements is a important first step. Study the compressor for indicators of harm, leaks, or uncommon noises. Search for any corrosion or particles accumulation across the unit.

- Refrigerant Degree Examine: Make sure the refrigerant ranges are throughout the really helpful vary. Incorrect refrigerant ranges can have an effect on the compressor’s efficiency and security mechanisms.

- Electrical Connections: Examine electrical connections for any indicators of harm, corrosion, or free wires. Safe all connections to stop electrical hazards.

- Lubrication: Common lubrication of shifting components, as really helpful by the producer, is important to take care of clean operation and forestall friction-related harm.

- Environmental Components: Monitor environmental circumstances resembling temperature and humidity to know their potential influence on compressor efficiency. Take acceptable measures to mitigate any antagonistic results.

Visible Inspection Process

A complete visible inspection is a vital part of preventive upkeep. This entails a cautious examination of the compressor and its surrounding elements for any indicators of harm, leaks, or uncommon noises. The method ought to embody checking for indicators of corrosion, particles accumulation, and any free or broken components. Documenting findings and taking corrective motion are essential steps in sustaining a functioning and secure cooling system.

- Find the Compressor: Determine the placement of the air conditioner compressor.

- Assess Bodily Situation: Examine the compressor for any seen indicators of harm, leaks, or corrosion.

- Hear for Sounds: Fastidiously pay attention for any uncommon noises, resembling grinding, knocking, or extreme buzzing, that would point out an issue.

- Study Environment: Examine the world across the compressor for any indicators of leaks, particles, or potential hazards.

- Doc Findings: Notice any noticed points and take acceptable motion as wanted.

Remaining Abstract

In conclusion, diagnosing why your air conditioner compressor will not flip off requires a scientific strategy, combining electrical diagnostics with environmental concerns and upkeep practices. By understanding the compressor’s management techniques, frequent causes of failure, and potential exterior components, you possibly can successfully troubleshoot the difficulty and restore cooling consolation. Bear in mind, correct upkeep and well timed intervention are essential for maximizing the lifespan and effectivity of your air con system.

FAQ Information: Air Conditioner Compressor Will not Flip Off

What if the overload relay is ok however the compressor nonetheless will not flip off?

Additional investigation into the management system, together with the management board and security sensors, is critical. A professional technician could also be wanted to diagnose extra complicated points.

How typically ought to I carry out preventative upkeep on my air conditioner compressor?

Common preventative upkeep, together with visible inspections and servicing, is really helpful no less than yearly, or extra continuously relying on utilization and environmental circumstances.

Can refrigerant leaks have an effect on the compressor’s shutdown mechanism?

Sure, improper refrigerant ranges can influence the compressor’s means to close down correctly. A leak can result in stress imbalances and set off security mechanisms to stop harm, probably resulting in the compressor not turning off.

What are some frequent environmental components which may have an effect on my AC compressor?

Excessive temperatures, excessive humidity, and important mud buildup can influence the efficiency and security mechanisms of your AC compressor. Make sure the unit is correctly ventilated and preserve good airflow across the compressor.